In today’s fast-paced manufacturing world, optimizing the performance of your filling machines is crucial for maintaining a competitive edge. With the help of expert insights, we’ve compiled a comprehensive guide on how to boost the efficiency and accuracy of your filling operations.

Prioritize Regular Maintenance for Optimal Performance

Consistent maintenance is the foundation for keeping your filling machines running at peak performance. Adhere to the manufacturer’s guidelines and promptly address any issues that arise. Regular cleaning of components is essential to prevent buildup that can impact accuracy.

Optimize Filling Speed for Increased Productivity

The speed of your filling machine can significantly affect accuracy. Running too fast can lead to inconsistent fills, while going too slow reduces output. Experiment with different speeds to find the optimal balance between accuracy and productivity.

Enhance Operator Training for Maximum Efficiency

Well-trained operators are key to maximizing filling machine efficiency. Ensure your team is knowledgeable about proper machine operation, including settings adjustments that impact accuracy. Provide ongoing training to keep them updated on the latest techniques.

Implement Automated Systems for Streamlined Operations

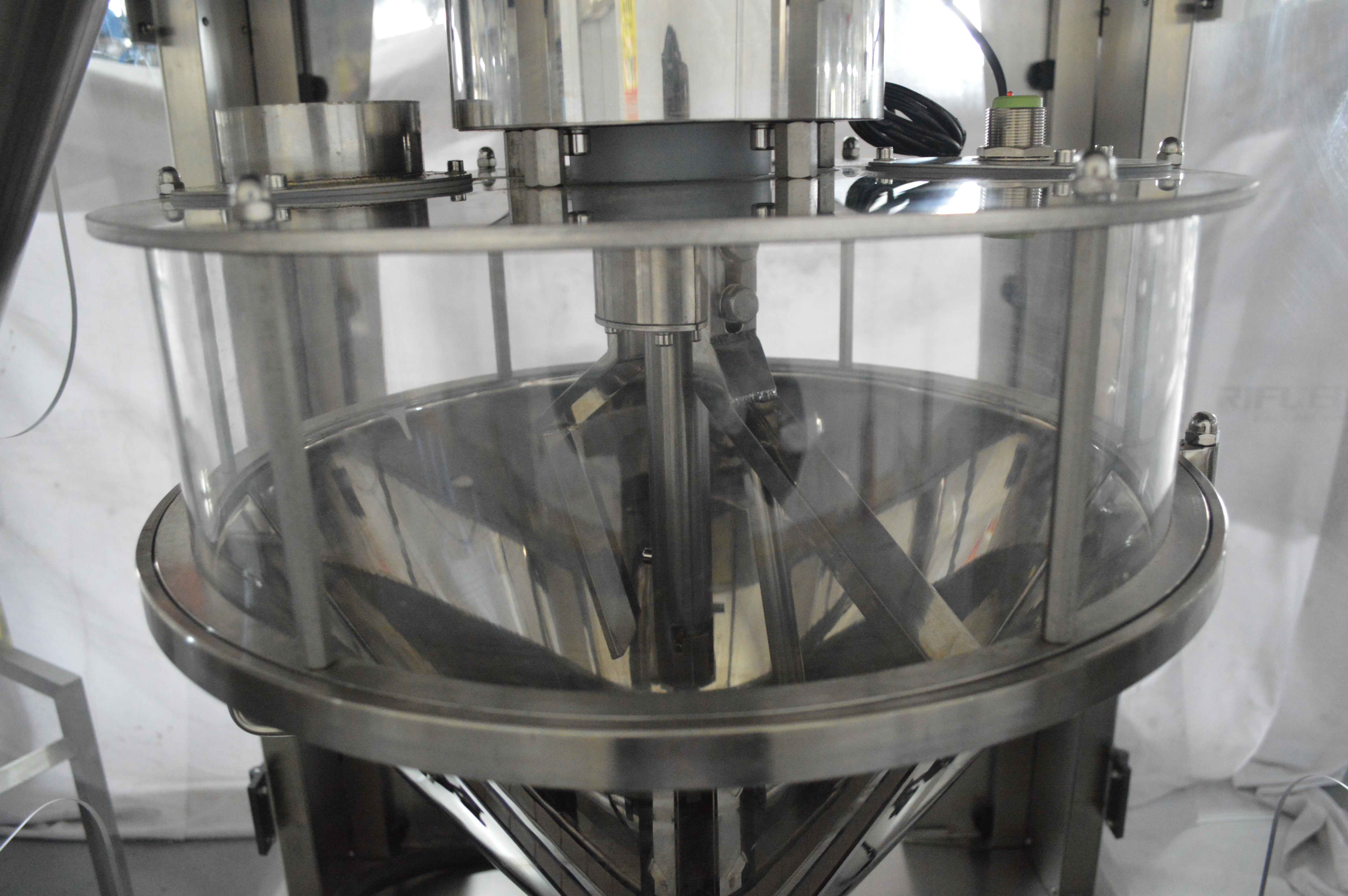

Automating aspects of your filling process, such as container loading/unloading and product flow control, can boost speed and throughput. Automated systems help maintain consistent parameters for enhanced accuracy and efficiency.

Regularly Calibrate and Adjust for Consistent Accuracy

Calibration is critical for maintaining filling accuracy. Regularly calibrate the machine using proper procedures and equipment to ensure consistent fill volumes and weights. Adjust settings like pressure and dwell time to optimize performance.

6.Leverage Viscosity Control Systems for Precision Filling

For liquids with varying viscosity, such as juices and syrups, viscosity control systems can help optimize filling accuracy by maintaining consistent liquid properties.

Enhance Operator Training for Maximum Efficiency

Well-trained operators are key to maximizing filling machine efficiency. Ensure your team is knowledgeable about proper machine operation, including settings adjustments that impact accuracy. Provide ongoing training to keep them updated on the latest techniques.

Monitor and Record Fill Accuracy for Data-Driven Improvements

Tracking your filling accuracy over time allows you to identify trends and make necessary adjustments. Use software or manual logs to record fill data for each production run, enabling data-driven optimization.

By implementing these expert tips, manufacturers can significantly boost the performance of their filling machines, leading to increased efficiency, reduced waste, and improved product quality. Stay ahead of the curve by prioritizing filling machine optimization in your production strategy.